24 May The Risks of Cleaning Stainless Steel

Stainless steel is such a remarkable material that it has found wide-spread use in a huge range of applications from small utensils to large industrial meat processing machines. In fact, stainless steel is ubiquitous in the commercial food and catering industry worldwide. What makes stainless steel so remarkable over ‘plain’ steel will require delving into the structure of stainless steel and the chemistry of corrosion – the enemy of stainless steel. It is a common misconception that stainless steel lives up to its name as being stainless, it is, however, more accurate to say ‘stain resistant’. There are numerous chemicals used in cleaning and disinfection processes that can permanently stain stainless steel, and staining will often lead to corrosion. If corrosion is allowed to progress and impacts structural elements of a machine or fixture (e.g. struts, load-bearing members, etc) catastrophic failure can result.

We’ve all seen rusty iron nails and, if you’re old enough to remember, car body panels going rusty and disintegrating rather too quickly. The underlining metal in nails and old car body panels is iron, what turns iron into plain steel is the addition of carbon to the molten pure iron. Mixing a certain amount of carbon into molten iron is called alloying, and this same idea of changing the properties of the base metal by the addition of elements is used to create hundreds of different stainless steel types in use today.

Alloying starts with a base metal (plain steel in this case) and adds certain elements in specific quantities to the molten mix. By choosing the elements used and varying the ratio of each one, the physical, mechanical and chemical properties of the steel alloy can be adjusted to meet the environmental and working conditions. This work has largely been standardised and a set of international standards establishes a series of grades for specific compositions. By the far the most common grade used that you will come up against is 304, it is used to fabricate nearly every kitchen and catering equipment. What sets this grade apart from the others, and what is crucial to understand from a cleaning point of view, is the addition of Chromium to the mix (nickel is also added to make the stainless steel easier to fabricate). It is a common misconception that Chromium sits on top of the steel protecting the underlining steel beneath. It is more accurate to say that Chromium is completely dispersed throughout the metal, but when exposed to oxygen in the air, forms a thin Chromium Oxide layer on the surface. This oxide layer is a very hardwearing protective layer that gives the steel a good degree of protection from the environment – it what makes stainless steel so versatile and resistant to cleaning, but it is not fool proof.

One remarkable property this protective layer possess is the ability to immediately ‘heal’ itself if scratched, as the newly exposed Chromium reacts to the oxygen and immediately reforms the oxide layer. This process is called passivation and its importance will come up later with quite specific cleaning chemicals used that help to promote new growth of this layer. With that in mind, if anything damages this oxide layer and prevents it reforming either by mechanical means (impacts, cuts, deep scratches, etc) or by chemical attack, corrosion will start. When the oxide layer is damaged the underlining steel is now exposed to the air (and dissolved oxygen in the water during cleaning), if contamination like chemicals is in contact with the damaged area the oxide layer will be prevented from reforming. Once corrosion has started it does not need further mechanical damage or chemical attack for corrosion to continue, all it requires is water.

How is stainless steel damaged through cleaning? Fundamentally cleaning uses both mechanical and chemical actions together to remove soiling from the surface. For example, if cleaning the outside of a stainless steel vessel, you would often use a brush or pad to provide mechanical abrasive action and a chemical to break down and disperse the soiling. Even the use of pressurised water jets instead of cleaning by hand with pads still imparts a mechanical action on the surface.

Each of these actions independently and collectively, if misused, could result in damage to the protective oxide layer and thus leading to corrosion becoming established. Although the basis for this article is focused primarily on the damage caused by chemical action, but for the purposes of mechanical action, the oxide layer can be worn down or broken by using pads that are too abrasive (abrasive plastic or metal pads) or metal scrapers used incorrectly. To prevent damage through mechanical action, stainless steel should be treated with care, using only suitably approved cleaning equipment for stainless steel. The choice of equipment and the method used should be outlined as part of a cleaning validation process.

Factors

There are several factors that can start or promote corrosion in stainless steel: Chemicals used, pH of solution, temperature, routine cleaning practices, and fabrication and design of the equipment being cleaned.

Within the sphere of routine and deep cleaning processes we can group together the chemicals used, the pH of the cleaning solution and the cleaning practices used, but it is important to consider the design of the equipment being cleaned too.

Chemicals Used

Compared to plain steel, 304 grade stainless steel is resistant to a wide range of common chemicals used in cleaning and disinfection processes, but there are a number of specific chemicals that can cause corrosion: Chlorides and certain strong acids. Chlorides by far represent the greatest risk to stainless steel and is the focus of this article.

Chlorides are negatively charged ions (Cl-) formed when Chlorine (Cl) gains an extra electron. As an example, normal table salt is Sodium Chloride which is composed of Na+ and Cl- ions. Chloride ions are also present in Hydrochloric acid, Sodium Hypochlorite (Bleach) and chloride salts. 304 grade stainless steel is highly vulnerable to the presence of these chloride ions, even in very low concentrations chloride ions are extremely aggressive and they uniquely possess the ability to directly attack the protective oxide layer. Evidence of Chloride attack can be seen as a distribution of highly localised ‘spots’ that are often only 1 mm in size spread out of the exposed surface, often surrounded by a red-brown ‘halo’.

This form of corrosion is called pitting corrosion, each pit or ‘spot’ is a microscopic hole in the metal that has been completely lost. By the time you have noticed these pits, and the ruddy brown staining surrounding it, sadly, corrosion has been firmly established and can grow and sustain itself with water alone – the damage is done. Why doesn’t the protective layer reform? Due to the corrosion reaction inside of the pits the region comes positively charged due to the presence iron ions (Fe2+), Chloride ions, being oppositely charged, are attracted to this region. The region becomes highly acidic with the pH of the pit dropping below pH 2 and it is this environment that causes the loss of metal to continue and prevent of the oxide layer from forming.

pH

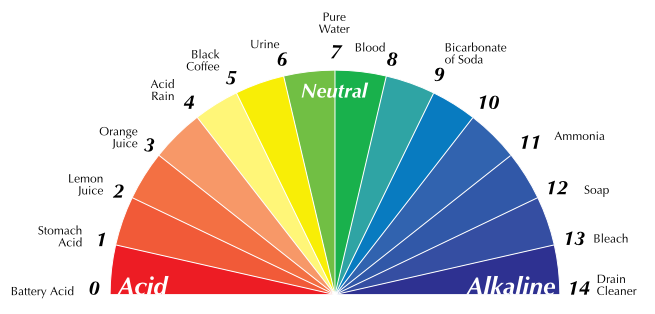

The pH of a solution tells you how acidic or alkaline the solution is. On a scale from 0 to 14, with water being around 7, a solution is acidic and increasingly so from 6 towards 0, a solution is alkaline from 8 towards 14, increasing in alkalinity towards 14. It must be remembered that the pH scale is not a linear scale, it’s a log scale with each change in number (i.e. from 4 to 3, or 11 to 12) a change by a factor of 10. E.g. a change from 4 to 2 (being more acidic) is a 100 times increase in acidity.

Stainless steel is highly resistant to alkaline conditions, any solution with a pH range of 8 to about 12 will be compatible. However, there is a narrow region where corrosion can start when using very alkaline solutions of pH 13 to 14. The greatest risk by far is using acidic solutions.

As the pH drops from 7 (neutral) towards increasing acidity the risk of corrosion increases dramatically with corrosion starting at a relatively mild acidic level of pH 5.

Metals and metal oxides in contact of acids, as you might expect when descaling machinery, will react resulting in some metal loss and corrosion setting in. Stainless steel, however, is more resistant to acidic conditions compared to plain steel, but up to a point. Stainless steel will resist mild acids (typical up to pH 3 or 4) and some stronger acids if intermittently exposed and left in contact.

Low pH acids have a significant impact on the resistant stainless steel has against corrosion, acids with a pH lower than 2 will attack the oxide protective layer and the underlining metal allowing corrosion to start. For food production cleaning and hygiene purposes there are different types of acids that are available.

Temperature

There are two aspects to temperature that are related to corrosion, reactivity of the cleaning solution and thermal breakdown (decomposition). As temperatures rise above room temperature any cleaning solution (but not detergents) that is acid or alkalis-based, chloride or sulphate based, will react with the stainless steel and soiling at an increasing rate. A hot acid or chloride solution (at around 50 to 60 degrees centigrade) will be so aggressive towards the stainless steel (and to the cleaner) that corrosion is almost assured. As the temperature rises way past 100 degrees centigrade the chemistry becomes complex but essentially the protective layer breaks down through a process called decomposition, this is less of a cleaning issue.